|

There are various Pros

& Cons regarding Composites Vs Wood.

Just remember there are other forces at work besides

what you read here.

The purpose of

this article is to educate the reader on composites,

and why they are a compelling alternative to wood.

Composites work very well with wood, or can replace

wood if needed.

For example here in Las Vegas we are firmly

recommending

Rainsong acoustic guitars as the absolute best

sounding instruments that won't give you problems

with drying out or being affected by the local heat.

The word

“composite” means two or more materials combined to

form a composite material. Fiber reinforced

materials, commonly referred to as composites, have

been around for centuries. Early settlers found that

by combining straw with mud, the composite was much

stronger. Highways & bridges are composite because of

the steel rebar embedded in the concrete. In today’s

modern age, light weight composites in the form of

fiber reinforced resins have become the standard in

sporting goods and aerospace applications.

Modern

composite materials use high strength fibers made from

a variety of materials such as fiberglass, carbon,

aramid, boron, and others. The most popular is carbon

fiber, due to its high stiffness, high strength, and

light weight. Carbon fibers may be manufactured from

polyacrylonitrile (PAN), pitch, or rayon precursor

materials by high-temperature (2000 to 35000 F)

carbonization or graphitization processes, hence the

name “graphite.”

Carbon fiber is

useless without a resin binder. Typically, carbon

fibers are coated with an epoxy resin which surrounds

the fibers and holds them in place. This material is

known as a pre-preg, which stands for

“pre-impregnated” meaning the fibers have been

embedded into the epoxy resin.

With

pre-preg materials, the carbon fibers are

unidirectional, meaning all the fibers run in the same

direction parallel to each other. This is the most

efficient arrangement of fibers. Fiber-Sonic,

takes the pre-preg sheets and cut them to different

shapes and at different fiber angles to create a

“lay-up” specific to each individual product. For

example, they can change the stiffness

of a neck by simply

changing the fiber angle. We can also combine

different fibers to create a hybrid composite, which

has beneficial properties of both. In

addition, once the recipe is optimized the composite

structure is repeatable part after part, ensuring

consistent high quality time after time.

This is what an

ideal composite structure looks like up close,

magnified 500X. The fibers should be distributed in

the resin matrix uniformly. This allows the matrix

material to transfer the load to the fibers in a

uniform manner, resulting in an efficient structure.

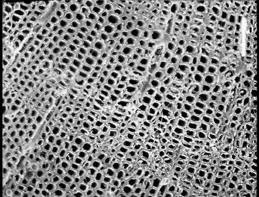

Wood has a

fiber structure very similar to a composite material.

Wood is comprised of a fibrous structure of cellulose,

which has a grain to it where the wood is stronger in

one direction than another. This is because the

cellulose fibers are parallel to each other, much in

the same way unidirectional composites are formed.

Wood comes in a

variety of species, all which have different grain structures, densities, strengths, and

beauty. Even the same species of wood varies based on

growing conditions. Furthermore, within the same

tree, the properties of wood can vary. Despite these

inconsistencies, wood is an excellent material for

musical instruments, but has limitations:

different grain structures, densities, strengths, and

beauty. Even the same species of wood varies based on

growing conditions. Furthermore, within the same

tree, the properties of wood can vary. Despite these

inconsistencies, wood is an excellent material for

musical instruments, but has limitations:

Wood

is a natural material, meaning that variance can occur

from batch to batch. Trees grow at different rates

depending on weather, so every batch can be different.

Wood is

affected by moisture, so factories must treat the wood

& store in temperature & moisture controlled

environments while manufacturing the product. Once

the product is shipped, it remains susceptible to

these environmental conditions, which can cause the

wood to warp, crack, and change dimension.

Wood can expand

and contract with temperature & moisture, effecting

the production of wood parts, and affecting the sound

of musical instruments. It is easy to see why wood

instruments require constant tuning.

The fiber

orientation of wood is limited to what nature gives

us. It is possible to create a laminate of different

plies of wood at different grain orientations (e.g.

plywood) but the above deficiencies still exist.

Fiber Sonic,

can design in the exact tone desired by changing the

stiffness and weight of the component. Sound travels

through a structure as a function of stiffness and

weight, so it is possible to “dial in” the optimal

combination for every application. With fiber

reinforced composites, there are numerous ways to

adjust the tone of the product:

Type

of fiber used:

You can use very stiff and light carbon fibers, or

heavier and more flexible glass fibers, or a

combination of each to optimize the performance and

cost.

Orientation of fiber

angles:

A low angle like 0 degrees maximizes stiffness, where

an intermediate angle such as 45 degrees is much more

flexible.

Stacking

sequence:

different plies are stacked up creating the layup, the

sequence and location of each fiber type can affect

the stiffness and tone.

Different resin

systems:

We can use a strong resin such as epoxy, which

will produce good attack and sustain, or use a softer

resin like a thermoplastic, which will produce a

warmer tone.

The world of

composites offers unlimited options to optimize the

performance of a musical instrument. They can be used

alone or in combination with wood, to take advantage

of the best parts of both.

See LSR Guitars,

Beautiful Wood Bodies, with Composite & Real Graphite Necks.

|